How Screen Printing Works: A Complete Guide

Screen printing creates bold, vibrant designs on many surfaces. This printing method has existed for centuries. Today, it remains a popular choice for custom packaging and apparel. Understanding the screen printing process helps you appreciate its value. This guide explains each step clearly. You will see why it’s a top choice for durable, high-quality prints.

What Is Screen Printing?

Screen printing is a stencil-based printing technique. It uses a mesh screen to transfer ink onto a substrate. Each color in a design requires a separate screen. This process creates layers of ink. Consequently, it produces vibrant, opaque prints that last. People often use it for t-shirts, posters, and custom boxes.

How Does Screen Printing Work?

The screen printing process involves several precise steps. Each step prepares the screen and ink for transfer. Following these steps ensures a clean, professional result.

Step 1 – Creating the Design

First, artists create a design on a computer. They separate the design by color. Each color will need its own screen. Simple designs with few colors work best for this method.

Step 2 – Choosing and Preparing the Screen

Next, printers select a mesh screen. The screen’s mesh count affects ink flow and detail. They clean and dry the screen thoroughly. This prevents any debris from ruining the stencil.

Step 3 – Applying the Emulsion and Exposing It

Then, they coat the screen with a light-sensitive emulsion. They place the film positive (the design) on the screen. They expose it to bright light. The light hardens the emulsion except under the black parts of the design.

Step 4 – Developing the Stencil

After exposure, they wash the screen. Water washes away the soft, unhardened emulsion. This process reveals the final stencil. The stencil is a negative of the original design.

Step 5 – Setting Up for Printing

Now, they secure the screen onto a screen print machine. They place the item to be printed underneath. Registration marks help align the screen perfectly. This ensures each color layer prints in the right spot.

Step 6 – Transferring the Design onto the Surface

The printer pours screen printing ink onto the screen. They use a squeegee to pull the ink across the stencil. The ink passes through the open mesh areas. It deposits onto the surface below. They repeat this for every color.

Step 7 – Heat Curing and Finishing

Finally, the printed item goes through a dryer. Heat curing permanently sets the ink. This makes the design durable and wash-resistant. The result is a vibrant, long-lasting print.

Types of Screen Printing Techniques

Screen printing offers various techniques for different effects.

Spot Color Screen Printing

This is the most common technique. It uses solid ink colors. It is perfect for simple logos and bold graphics.

Grayscale Printing

This technique uses black and white ink. It creates shades of gray. It is ideal for photographic images.

Halftone Printing

This method uses dots of varying sizes. It simulates continuous-tone imagery with a single ink color.

CMYK (Four-Color) Screen Printing

This process uses Cyan, Magenta, Yellow, and Black inks. It can create a wide spectrum of colors. It is complex but effective for full-color designs.

Duotone Screen Printing

This uses two ink colors to create depth. It often uses black and a spot color for a rich effect.

Simulated Process Printing

This technique uses spot colors to simulate full-color images. It is great for detailed artwork on dark garments.

Advantages of Screen Printing

Screen printing has many benefits for businesses.

It produces vibrant, opaque colors on dark materials.

The prints are highly durable and long-lasting.

It is cost-effective for medium to large batches.

It works on many surfaces like fabric, paper, and plastic.

You can use specialty inks like metallic or puff inks.

Frequently Asked Questions

Where can I find screen printing classes near me?

Many local art centers, community colleges, and print shops offer screen printing classes near me. You can also find online tutorials to learn the basics.

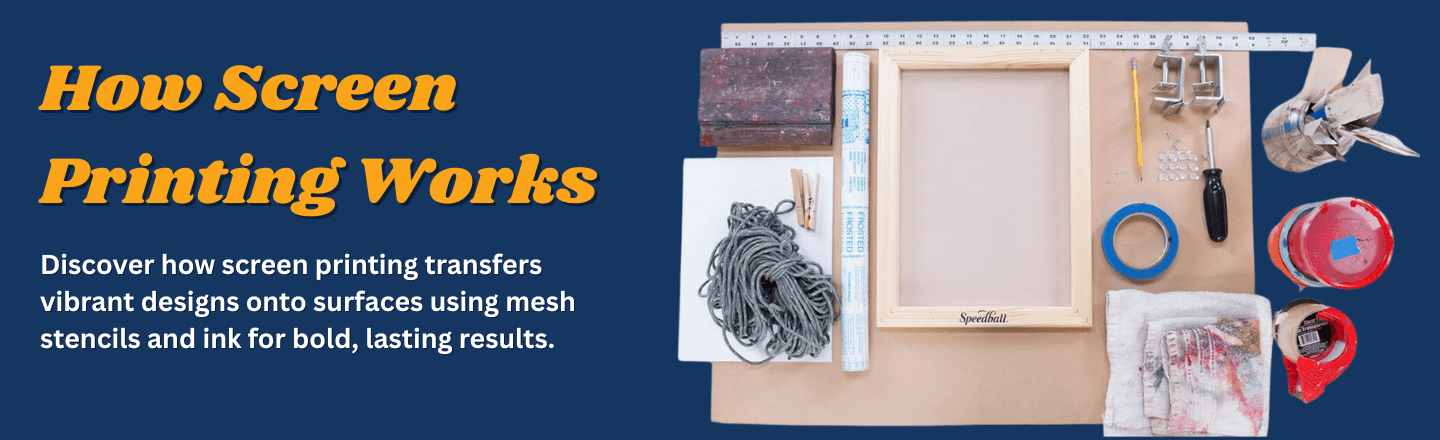

What is in a basic screen printing kit?

A basic screen printing kit usually includes a screen, a squeegee, emulsion, ink, and a starter frame. It provides everything for simple DIY projects.

How does a printing machine screen work?

A printing machine screen holds the stencil taut. The machine aligns it perfectly and helps apply even pressure with the squeegee for consistent prints.

What is the relationship between the screen and printer in this process?

The screen and printer work together. The screen holds the stencil, and the printer (the machine or person) applies the ink through it onto the substrate.

Ready to Start Your Printing Project?

Screen printing offers unmatched durability and vibrancy. It is perfect for creating a lasting brand impression. Understanding the process helps you make informed decisions. Are you ready to bring your designs to life? The experts at Vital Custom Boxes can help. Browse our shop for ideas. Then, get a quote for your custom screen-printed packaging today.