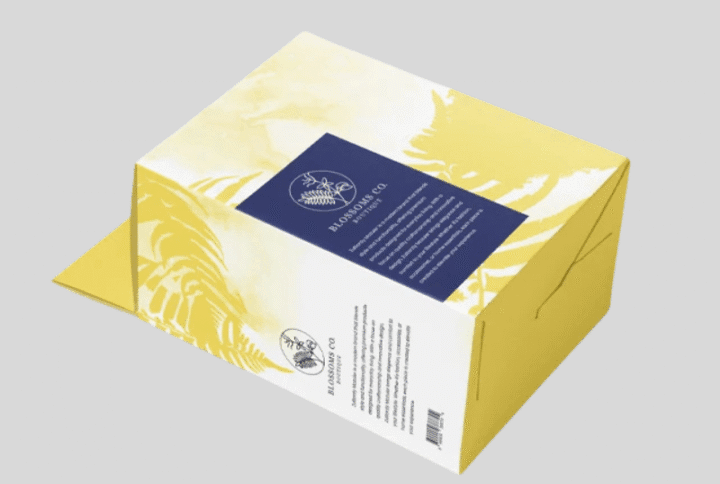

Reverse Tuck End Boxes

In packaging design, small structural differences create significant functional advantages. The reverse tuck end box represents a sophisticated evolution of the classic folding carton, offering enhanced security and visual appeal. Unlike traditional straight tuck designs, this configuration positions the tuck flaps on opposite sides, creating a more balanced and secure closure system. At Vital Custom Boxes, we specialize in engineering precision custom reverse tuck end boxes that combine mathematical precision with marketing brilliance. Our expertise in folding cartons ensures your products receive both superior protection and standout shelf presence. From reverse tuck end mailer boxes for e-commerce to elegant gift boxes for retail, we deliver packaging solutions that meets or exceeds industry standards while creating memorable unboxing experience for your customers.

- Free worldwide shipping on all orders over $100

- Delivers in: 3-7 Working Days Shipping & Return

Get Custom Quote

Why Reverse Tuck End Boxes Outperform Standard Designs

This advanced tuck end box configuration offers distinct advantages that benefit both businesses and consumers.

Enhanced Product Security: The reverse flap configuration creates a more secure closure. Moreover, it prevents accidental opening during shipping and handling.

Improved Structural Integrity: Opposite flaps distribute pressure more evenly. Therefore, the box maintains its shape better under stress.

Superior Shelf Presence: The balanced design presents a cleaner appearance. Furthermore, it allows for more creative graphic design options.

Easy Customer Access: These boxes remain easy to open while staying securely closed. Consequently, customers appreciate the user-friendly design.

Exceptional Features of Our Reverse Tuck Boxes

We engineer every box with precision and attention to detail.

Advanced Locking Mechanism: Our pye lock tuck for positive locking ensures secure closure. Additionally, it provides satisfying tactile feedback when opening and closing.

Premium Material Selection: Choose from high quality reverse tuck end chipboard boxes or durable corrugated reverse tuck end box options. Moreover, we offer eco friendly and recycled materials.

Precision Engineering: Every reverse end tuck bottom box features exact dimensions and crisp folds. Thus, your boxes assemble perfectly every time.

Efficient Shipping: All boxes arrive shipped flat to save space and reduce costs. Consequently, you optimize storage and shipping expenses.

Custom Sizing: We create white reverse tuck end cardboard boxes in any dimensions. Therefore, your products fit securely without movement.

The Vital Custom Boxes Advantage

Our manufacturing expertise delivers consistent quality and performance.

Expert Design Support: We provide comprehensive guidance on box engineering. Accordingly, your custom packaging performs flawlessly.

Rigorous Quality Control: Every production run meets or exceeds industry standards. Therefore, you receive reliably excellent packaging.

Fast Turnaround: We maintain efficient production schedules. Hence, your packaging arrives when you need it.

Comprehensive Solutions: Your reverse tuck boxes complement our full line of Folding Cartons. So, you can maintain packaging consistency across products.

Case Study: “Precision Electronics” Packaging Upgrade

The Challenge: An electronics manufacturer needed more secure packaging for their sensitive components. Their current straight tuck boxes were opening during shipment.

The Solution: We engineered custom reverse tuck end boxes with pye lock tuck for positive locking. The design used sturdy reverse tuck end chipboard boxes with custom foam inserts. Additionally, we implemented PPP B-566 compliant construction.

The Result: Shipping damage claims decreased by 85%. Furthermore, customer satisfaction scores improved significantly. The company now uses this packaging across their entire product line.

Simple Ordering Process

Creating your precision packaging involves four straightforward steps.

Consult & Design: First, download our reverse tuck end box template. Alternatively, consult with our design team.

Quote & Approve: Next, we provide detailed pricing and design proofs.

Production & Quality Check: Then, we manufacture your boxes feature with strict quality control.

Ship & Deliver: Finally, we dispatch your order shipped flat for efficiency.

Frequently Asked Questions (FAQs)

What is the difference between straight and reverse tuck boxes?

Straight tuck boxes have flaps on the same side, while reverse tuck boxes have flaps on opposite sides. Consequently, reverse tuck provides better security and balanced appearance.

Can I get custom printed reverse tuck boxes?

Absolutely. We specialize in custom reverse tuck end boxes with full printing capabilities. Moreover, we can match specific brand colors and requirements.

What industries use reverse tuck end boxes?

These boxes serve electronics, pharmaceuticals, food, and cosmetics industries. Additionally, they work perfectly for gift boxes and retail products.

Do you provide templates for design purposes?

Yes, we offer a reverse tuck end box template for design planning. Therefore, you can visualize your packaging before production begins.

Choose Smarter Packaging Design

The reverse tuck end box demonstrates how intelligent engineering creates better packaging solutions. It offers superior performance while maintaining cost-effectiveness. Don’t settle for outdated packaging designs that compromise your product’s security.

At Vital Custom Boxes, we deliver engineered custom packaging solutions that perform. Our expertise ensures your products arrive perfectly every time.

Ready to Upgrade Your Packaging?

Contact us today to discuss your reverse tuck end box project.

Phone: +1 (828) 455-0798

Email: ✉ sales@vitalcustomboxes.com

Get a quote and experience better packaging today!

| size | 8" x 6" x 2", 10" x 8" x 3", 12" x 10" x 4", 15" x 12" x 5" |

|---|---|

| material | Cardstock, Paperboard, Rigid Cardboard |

| color | White, Kraft Brown, Glossy White |

| Box Style | Reverse Tuck End, Tuck Top & Bottom |

| Material Weight | 24pt, 28pt, 32pt, 36pt |

| Finish | Matte, Glossy, Uncoated |

| Assembly | Easy Fold, No Glue Needed |

| Pack Quantity | 25 Boxes, 50 Boxes, 100 Boxes |

| Recommended Use | Retail Packaging, Cosmetic Boxes, Gift Boxes, Subscription Boxes |

Reviews

There are no reviews yet.